Description

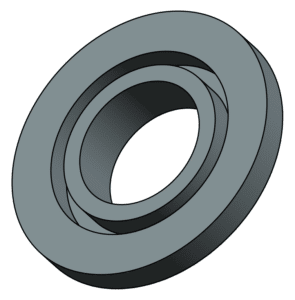

Kesaria Rubber Industries provides custom molded rubber gaskets that can be compression molding process from a variety of rubber materials. Rubber Gaskets play an important role in various industrial applications spanning. While most gaskets are similar in functioning, the material and shape may depend on the application.

At Kesaria, we feature an expansive product line of gaskets to ensure that have the best solution for any application. Here we are sharing a little detail about our gasket, including a material selection guide, how they are made, gasket uses, and how to select the best material for a specific application.

Advantages of Rubber Gaskets

Rubber Gasket help prevents leakages and loss of pressure in countless forms of process equipment, piping systems, machinery, and more. Some advantages are such as:

- Customizability

- Variety of colors options

- Variety of materials selection options

- Heat & Temperature / Targeted resistances

Rubber Gaskets Material

We manufacture a large variety of Rubber Gasket Seals of different shapes & sizes from a variety of rubber grades like VITON, SILICON, EPDM, NBR, NEOPRENE, SBR & NATURAL. The hardness rating on a Shore A scale for Gaskets can be 30 ~ 95 Durometer. Exact specifications should be clarified by our engineers, as the chemical and physical properties of Gaskets can differ based on manufacturing technique.

NEOPRENE, SBR & NATURAL. The hardness rating on a Shore A scale for Gaskets can be 30 ~ 95 Durometer. Exact specifications should be clarified by our engineers, as the chemical and physical properties of Gaskets can differ based on manufacturing technique.

Rubber Gaskets Material Selection Guide

| MATERIAL | NR | SBR | NBR | CR | EPDM | HNBR | ACM | CSM | SILICONE | FKM (VITON) |

| HARDNESS RANGE ( SHORE A) | 40-90 | 35-90 | 40-90 | 40-80 | 40-90 | 40-90 | 40-80 | 40-80 | 30-80 | 50-90 |

| HIGH TEMP C | 100 | 120 | 130 | 130 | 150 | 150 | 180 | 150 | 230 | 225 |

| LOW TEMP C | -50 | -55 | -45 | -40 | -50 | -45 | -25 | -40 | -60 | -15 |

| STEAM | F | F | F | P | G | G | P | E | E | E |

E= EXCELLENT; G= GOOD; F= Fair; P= Poor; A=Available, NA= Not Available

This guide is intended for general reference only. The materials listed are the most commonly used. There are numerous compound variations designed for specific applications for which? please? forward details to our engineers for a recommendation.

Industrial Applications

Kesaria’s gaskets are excellent resilience and sealing for various applications involving low temperatures, pressures, and mild chemical environments in piping and plumbing applications. Some of the most popular industrial applications for our rubber gaskets are:

- Bathroom Fitting

- Chemical processing

- Oil and gas

- Piping and plumbing

- Water and wastewater management

Reviews

There are no reviews yet.