Description

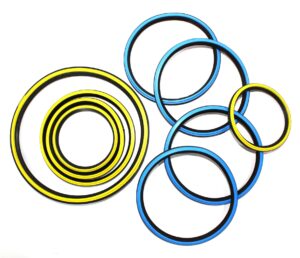

Plastic pipes ( HDPE, CPVC, UPVE, and PVC ) hold a major part in the plumbing sector due to lower cost, corrosion resistance, no painting required, etc. Kesaria rubber in a short span of time has become a prominent & reliable manufacturer and supplier of rubber and rubber & plastic seals to pipe & fitting manufacturers. Size 75mm, 90mm, 110mm and 160mm are regular and consumption is high however other sizes are supplied as per industrial design and application followed by the customer. Rubber & PP seals are manufactured through injection molding which offers durability, leakproof, finishing, and resistance toward high water pressure.

Application and standard

Important dimensions to consider when specifying seals include shaft OD, ID, housing bore Diameter or seal Outer Diameter, axial cross-section or Thickness, and radial cross-section. Important service limits parameters to consider include maximum operating speed, maximum operating pressure, vacuum rating, operating temperature, and any fluids with which they may come in contact. Rubber sealing element or lip material choices for seals include Aflas, VITON, SILICON, EPDM, TPR, NBR, NEOPRENE, PU, SBR & NATURAL. The hardness rating on a Shore A scale for Seals can be 30 ~ 95 Durometer. Exact specifications should be clarified by our engineers, as the chemical and physical properties of Seals can differ based on manufacturing technique.

pressure, vacuum rating, operating temperature, and any fluids with which they may come in contact. Rubber sealing element or lip material choices for seals include Aflas, VITON, SILICON, EPDM, TPR, NBR, NEOPRENE, PU, SBR & NATURAL. The hardness rating on a Shore A scale for Seals can be 30 ~ 95 Durometer. Exact specifications should be clarified by our engineers, as the chemical and physical properties of Seals can differ based on manufacturing technique.

Material?Selection?Guide

| MATERIAL | NR | SBR | NBR | CR | EPDM | HNBR | ACM | CSM | SILICONE | FKM (VITON) |

| HARDNESS RANGE ( SHORE A) | 40-90 | 35-90 | 40-90 | 40-80 | 40-90 | 40-90 | 40-80 | 40-80 | 30-80 | 50-90 |

| HIGH TEMP C | 100 | 120 | 130 | 130 | 150 | 150 | 180 | 150 | 230 | 225 |

| LOW TEMP C | -50 | -55 | -45 | -40 | -50 | -45 | -25 | -40 | -60 | -15 |

| STEAM | F | F | F | P | G | G | P | E | E | E |

E= EXCELLENT; G= GOOD; F= Fair; P= Poor; A=Available, NA= Not Available

This guide is intended for general reference Only. The materials listed are the most commonly used. There are numerous compound variations designed for specific applications for which please forward details to our engineers for a recommendation.

Reviews

There are no reviews yet.