Why Do O-Rings Fail?

To define simply, o-rings are simple yet critical components in the shape of ‘o’ that are used to create a seal between two surfaces to prevent leakages.

However, like any mechanical component, they can fail at times for various reasons. It’s very important for users to understand this because knowing the cause makes it easier to change the design/seal material to ensure its longevity and effectiveness.

In the list below, we identify various types of o-rings failures and how they can be prevented before they result in costly losses:

- Design Failure

WHAT

No visual damage. Performance failure.

WHY

Incorrect groove or gland design. Improper sizing. Incorrect tolerances. Hardware damage or misalignment. Improper mating surface finishes.

HOW TO PREVENT

Proper groove dimensions. Appropriate tolerances. Optimising the size or gland design for the particular application.

- Abrasion

WHAT

Light scratches. Deep cuts. Cropped surface.

WHY

Dynamic environments. Repetitive friction. Excessive temperature. Inadequate lubrication.

HOW TO PREVENT

Maintain proper lubrication. Eliminating abrasive elements.

- Chemical Degradation

WHAT

Cracks. Blisters. Stains. Discoloration. Hardening. Swelling.

WHY

Incompatibility with the chemical environment. High temperature. Excessive pressure.

HOW TO PREVENT

Use the right o-ring material that is highly resistant against specific chemicals within the application. Regular monitoring.

- Plasma Degradation

WHAT

Discoloration. Powdered residue on the surface. Erosion in the exposed areas.

WHY

Chemical reactivity of the plasma. Ion bombardment. Electron bombardment. Improper gland design. Incompatible material.

HOW TO PREVENT

Plasma compatible elastomer and compound. Minimise exposed area. Be careful of the gland design.

- Compression Set

WHAT

Failure to return to its original shape. Permanent deformation.

WHY

High temperatures. Stress. Tight groove. Excessive compression. Incompletely cured elastomer. Elastomer with high compression set.

HOW TO PREVENT

Higher durometer. Higher operating temperature. Proper o-ring groove design. Backup rings. Low compression set elastomer. Material compatibility. Use appropriate compression levels.

- Over Compression

WHAT

Parallel flat surfaces. Circumferential splits within the flattened surfaces.

WHY

Improper design. Excessive compression. Not resistant to thermal or chemical volume changes.

HOW TO PREVENT

Proper gland design. Right response to chemical and thermal environments.

- Explosive Decompression

WHAT

Blisters. Pits. Pocks.

WHY

Rapid pressure changes. Elastomer with low hardness.

HOW TO PREVENT

Elastomer with higher hardness. Slower release of pressure. ED resistant material.

- Installation Damage

WHAT

Indentations on the outer edge of the o-ring surface.

WHY

Improper lubrication. Installation in applications with sharp edges. Size too big or small to fit in its groove.

HOW TO PREVENT

Taping sharp edges. Lubrication. Proper elastomer sizing. Proper gland design.

- Extrusion

WHAT

Nibbled or ragged edges receiving lower pressures.

WHY

High pressure. Excessive clearances. Excessive gland fill. Irregular clearance gaps. Sharp gland edges. Unsuitable dimensions. Improper material.

HOW TO PREVENT

Higher durometer. Use of backup rings. Decrease clearances. Use of harder seal material. Proper gland design. Decrease sharp edges of the gland. Appropriate gland design.

- Outgassing

WHAT

No visible difference. Slight reduction in cross-sectional size in rare cases.

WHY

Low plasticized elastomer. High vacuum levels. Improperly cured elastomer.

HOW TO PREVENT

Right material. Proper temperature ranges. Avoid plasticized elastomers. Post-cured seals.

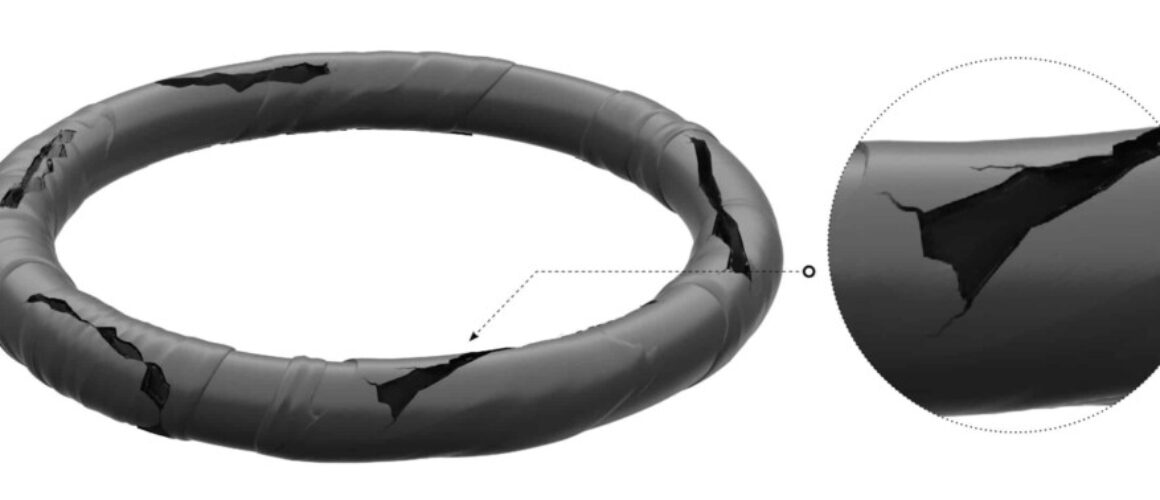

- Rapid Gas Decompression

WHAT

Cracks. Blisters. Deep cuts. Might blow out entirely in the worst-case scenario.

WHY

Exposure to gas at high pressures and temperatures for an extended amount of time.

HOW TO PREVENT

Use Rapid Gas Decompression (RGD) o-rings.

- Spiral Failure

WHAT

Deep cuts or marks spiralling around the outer surface.

WHY

Tight installation. High friction. Inadequate lubrication. Inconsistent surface. Excessive gland width.

HOW TO PREVENT

Higher durometer. Using x-rings. Correct installation procedures. Internally lubed elastomers. Proper gland design. Use of polymer backup rings.

- Thermal Degradation

WHAT

Rounded cracks along the surface. Softening.

WHY

High temperature. Thermal properties of the elastomer.

HOW TO PREVENT

Elastomer with enhanced thermal stability.

- Thermal Extrusion

WHAT

Nibbled or ruffled edges. Extrusion on the lower-pressure side of the o-ring.

WHY

Higher temperature.

HOW TO PREVENT

Proper groove design. Resistance of material to high temperature.

- UV Degradation

WHAT

Discoloration. Cracking and breaking in some cases.

WHY

Exposure to UV rays for prolonged period of time

HOW TO PREVENT

Using EPDM o-rings and Viton® o-rings in black color.

Need a customised product to improve your product’s performance in a particular application?

Just drop us a mail at info@kesaria.com!